Fighting Plastic Pollution

We believe that sustainability is both a lifestyle and a profitable business model. We see sustainability as a pathway to follow resolutely as responsible leaders and companies to tackle global challenges with the products we develop. Plastic pollution is one of the most pressing problems in our world.

The flow of plastics into the ocean is projected to triple by 2040 under a business-as-usual scenario. To stop this plastic pollution, industry and policymakers need to take drastic action. Increasing plastic recycled content in products to 40% by 2030 is one of our ambitious targets.

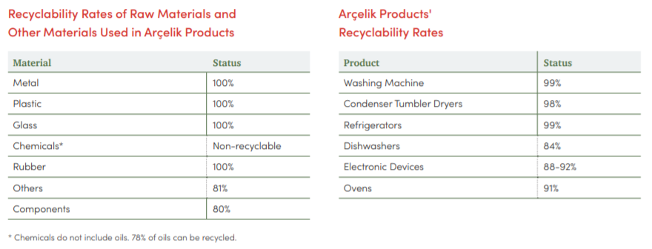

To achieve this aspirational goal, we have started the Recycled Content Project at our production facilities worldwide. Beko R&D develops high-performance and eco-friendly recycled plastic formulations to replace their virgin counterparts without sacrificing the durability of the products. Our holistic approach takes almost all the plastics in our products into consideration to maximize the plastic recycled content. We design recyclable products with reduced environmental impact and share product recyclability rates.

The innovative solutions focus on becoming pioneers in the industry. The examples include using PET bottles, waste fishnets, bio plastics, eggshells, tomato and coffee wastes in products.

The packaging wastes are also turned into valuable components to be used in products. The waste dishwasher components from Beko's own Waste Electrical and Electronic Equipment Recycling facilities are recycled to be used in Beko products again to close the loop in production.

Some of the examples to the value generated are provided below:

Using PET bottles in products

-

Approximately 58 million PET bottles have been recycled since 2017 when the project was first initiated until the end of 2020.

-

PET bottles are used in washing machines, dishwashers, air conditioners. The studies are expanded into Koc Holding Group companies.

-

The project was and is still the first of its kind in our industry.

-

It was the first project that combined using waste and turning it into a valuable source. It proved sustainability makes business sense in terms of both generating savings for the company and also increasing the brand value.

Using waste fishnets and textile wastes in products

-

8 tons of recycled waste fishing nets and 111.7 tons of recycled industrial thread waste used in in oven, washing machine and washer-dryer and dishwasher parts.

-

The first of its kind in the industry and a pioneering innovation.

Fiber Catcher

-

First of its kind microfiber filter integrated inside the washing machines and dryers to filter up to 90% of the microplastics. The product will be released in different markets in 2021.

Products made from Organic Composites

-

The BioFridge is made using both biobased polyurethane insulation material (Bio-Cool) and biocomposite raw materials that contain organic material such as soy and castor oil. The egg trays are made of 20% eggshell waste and 80% bio-based plastics made from organic resources such as corn starch and sugarcane, and the fan cover is produced with 100% bio-based plastics. The door seal material is also partly made of soybean oil. The CO2 emission per unit produced is reduced by 6 kg given biomaterials’ 80% lower carbon footprint compared to petroleum based traditional materials. The product will be released in different markets in 2021.

-

We use coffee grounds in coffee machines and tea fibers in tea makers. These innovative and eco-friendly products will be in serial production in 2021.

We support the commitment to “end the consumption of disposable plastics by the end of 2020”, as announced in late 2019 by Koç Holding, and our work continues to fulfil this commitment at Beko and to extend it to our suppliers. Due to the pandemic (COVID-19) that started at the end of 2019, we will work again on this target.

We Became Signatory of the Business Plastic Initiative (IPG)

In cooperation with the United Nations Environment Program (UNEP), more than 450 organizations gathered under a common vision to address plastic waste and pollution at its source in October 2018. The new Plastic Economy Global Commitment aims to bring a systematic change to the plastic problem by including companies, governments, NGOs, universities, industrial organizations, investors, and other institutions that represent 20% of plastic production.

IPG is a collaboration founded by Global Compact Türkiye, the Business Council for Sustainable Development (BCSD) Türkiye, and the Turkish Industry and Business Association (TÜSİAD) in 2019. It brings together the stakeholders of the entire plastic value chain to make commitments on taking concrete actions to minimize the production and consumption of plastics.

Being a signatory of IPG, we have set our 2023 commitments in product manufacturing

as of March 2021:

-

Increasing the recycled plastic content in products from 3,000 to 15,000 tons per year

-

Increasing the recycled plastic parts made from waste fishing nets from 8 tons to 25 tons per year

-

Increasing the recycled plastic parts made from waste PET bottles from 28 million to 60 million per year

-

Using 750 tons of biopolymer and bio composite raw materials including PLA per year

-

Using plastics generated from our WEEE recycling plants in dishwasher, oven and tumble dryer product categories

-

Recycling 600 tons of packaging waste generated from our manufacturing plants to be used in plastic parts

-

Completing and approving R&D processes for using 30% recycled material content in plastic packaging including EPS, shrink, and strip

-

Completing R&D processes for using recycled chemical raw materials in food contact product parts

TR

TR