Edition #1 – For internal use only

Innovative Arçelik initiatives that fight against plastic pollution

Re-purposing of plastic waste is important for the economy and the environment and Arçelik is contributing to these efforts through its Leo-PET and Ghost Fishing Nets projects.

To reduce CO2 emissions, energy consumption and contribute to a more environment-friendly economy, Arcelik is using the material, Leo-PET which is made from recycled plastics in air conditioners and washing machines, in addition to the use of fishing nets in oven parts.

Use of Leo-PET in washing machine production

This project involves the integration of recycled PET bottles into the production of washing machine tubs. The use of hybrid composite materials with recycled PET functions means that there is no compromise on the machine’s performance.

Using the hybrid composite material generated for this project, the amount of glass fibers procured decreased, resulting in a reduction of the current account deficit. The domestic recycling industry and the national economy are both supported whilst also contributing to the environment.

Processing glass fibers requires very high temperatures, resulting in high energy consumption and carbon emissions. With the use of Leo-PET, 2,050 gigajoules were saved; CO2 emissions were reduced by 885 tons and 25,000,000 bottles were recycled which equates to 250 tons of plastic.

Use of Leo-PET in the production of air conditioners

The innovative Leo-PET material is also being used in the production of air conditioners.

As of the second quarter of 2019, a total of 25,000 air conditioners were produced using innovative Leo-PET material; 250,000 pet bottles were recycled, 37,500 kWh of energy was saved, and CO2 emissions were reduced by ten tons. The amount of CO2 saved correlates to approximately 1,000 air-conditioners in weight.

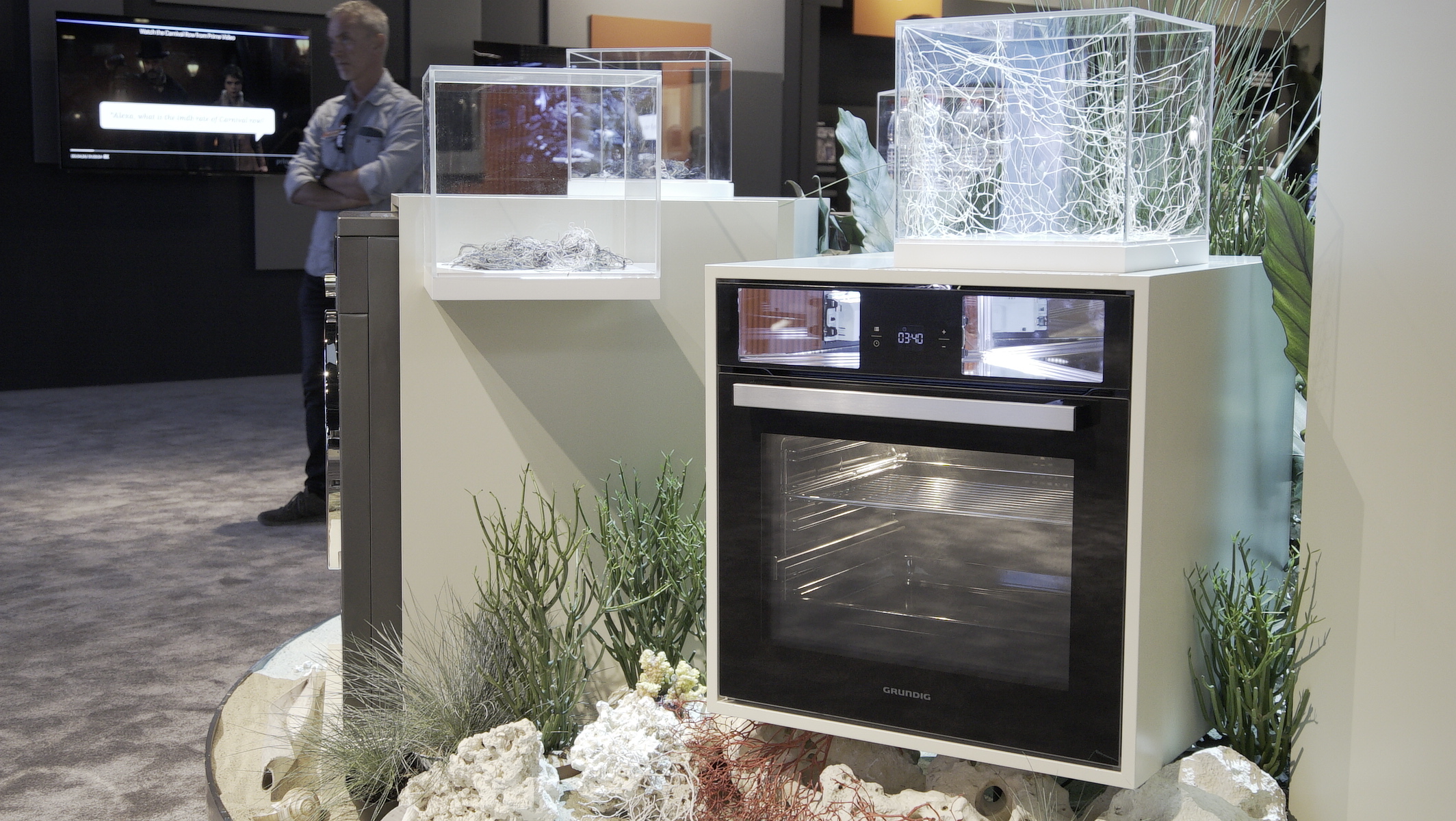

Recycling ghost fishing nets

Ghost fishing nets are nets that have been left or lost in the ocean by fishermen. These nets, often nearly invisible in dim light, can be left tangled on reefs or drifting in the open sea, causing serious damage to the marine environment. As a response to this global problem, Arçelik is utilizing recycled ghost fishing nets in the production of ovens.

Most ghost fishing nets are made from polyamide polymer, which is the most common type of plastic used in ovens, thanks to its high mechanical and thermal properties. The recycled ghost fishing nets were used in 170,000 ovens in 2019 and created a saving of one euro per kilogram (€/kg).

Various plastic parts for ovens have been produced via this project which require high stiffness and high thermal stability. A combination of recycled plastics from ghost fishing nets and waste yarn fibers were used with the intention to maximize the performance of the end product.

By contributing to the circular economy using our R&D capabilities, Arçelik is making steady progress towards its goal of producing products that use a high proportion of recycled parts, by turning waste into raw materials for usage.

EN

EN  TR

TR

Share